Cryogenic System

- HOME

- Cryogenic System

Cryogenic Process Solutions:

Back

INDUSCRYO Provides Cryogenic Storage and delivery solutions for your Process. If you have a new project or requirement, wish to expand the existing capacity of your system or upgrade the system we are here to support you. Our Expert team in Cryogenic Process Solution will guide you and offer the best techno-commercial solution.

We can design your system as per process requirement and provide the initial design Parameters, P&ID, Thermal and Flow Calculations, Cryogenic safety requirements and feasibility studies.

We also provide the safety and statutory certificates for installation and operating the Cryogenic systems. Contact us!

Cryogenic Storage Dewar and Accessories:

Back

We are one of the suppliers of super insulated Cryogenic storage and transport vessels, Cryogenic Tanks of capacity from 100 to 20000 (20KL) litres. for cryogenic liquefied gases (Nitrogen, Oxygen, Argon).

We Supply small LN2 Aluminium double wall storage containers/Dewar of capacity 2 to 50 litres for biological samples and cryopreservation.

We offer Cryogenic Tanks Vacuum Testing, Helium MSLD leak test, repair & vacuum evacuation.

We have every Cryogenic Tank and Dewar accessory needed to handle liquid nitrogen or other cryogenic liquid. We also provide Personal Protective Equipment (PPE) such as aprons, cryo-gloves, and masks are always in stock. We Provide all the Spares like safety Valves, Manual Valves and Pressure Regulators.

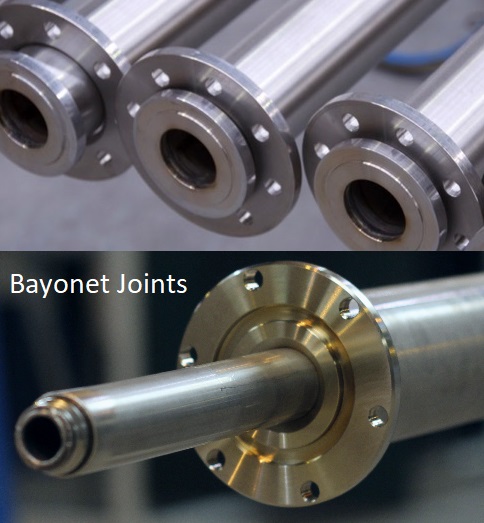

Vacuum Jacketed Lines And Transfer Tube:

Back

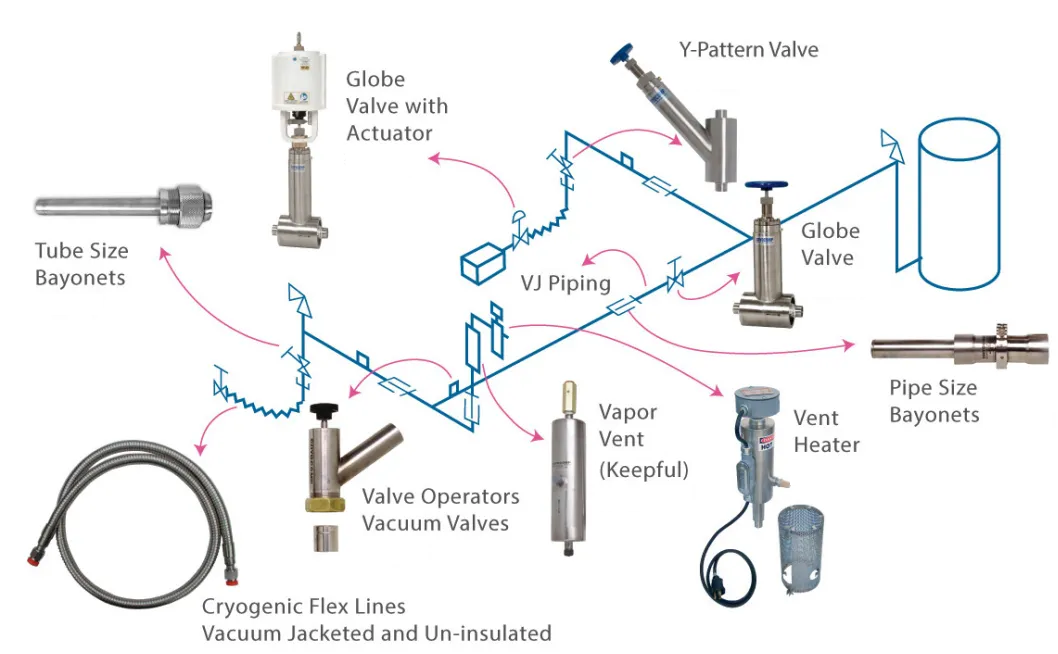

Cryogenic Distribution System:

Back

We offer complete Design, Automation, Process analysis and development of Cryogen distribution systems for Chemical/Pharmaceutical Processes, Thermal test chambers and cryogenic testing of Valves and materials.

For medical and healthcare industry mainly Cryogenic Reactors, Bulk Drugs Formulation cryogrinding, Vaccine centres, Hospitals, Cryopreservation and Cryobiology.

For the food industry we offer solutions for the Cryogenic Grinding of Spices, Cryogenic Dosing of LN2 for the mineral water, food and beverages packaging, Cryo-freezing equipment for the meat.

Cryogenic Grinding Of Spices:

Back

Cryogenic testing equipment for valves:

Back

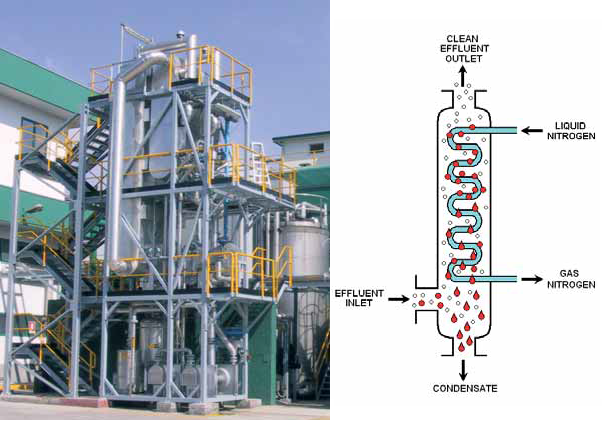

Cryogenic condensation and recovery of volatile organic compounds, VOCs:

Back

Cryogenic Globe Valves, Safety Valves (TRV, SRV) and Regulators:

Back

One-stop shopping is here for your convenience.

We have every Cryogenic Tank and Dewar accessory needed to handle liquid nitrogen or other cryogenic liquid.

We Provide all the Spares like Safety Relief Valves, Thermal Relief Valves, Manual Globe Valves, Cryogenic Solenoid Valves, Pressure Regulators, DPT Level Gauges and CGA connectors.

We also provide Personal Protective Equipment (PPE) such as aprons, cryo-gloves, and masks are always in stock.

Cryogenic Instrumentation and Automation:

Back

⦁Liquid Nitrogen Level sensor: Please contact us for the capacitive and differential pressure(DPT) type LN2 level sensors.

⦁ Complete thermometry PT 100 sensor, PID controller for your critical Cryogenic systems.

⦁ Autofillng systems for the cryogenic Reactors and Tanks.

⦁ Oxygen Monitoring system for the cryogenic operational area.

⦁ Vacuum Pirani Gauges and Display Monitor.

⦁ Automation with PLC and SCADA for the Cryogenic Systems.

⦁ Cloud and IoT services for monitoring of your system online.

Cryo Cooler, Cryo Pump & Helium Compressors:

Back