Cryogenic Valves

- HOME

- Cryogenic valves

Distributorship and Agency for Indian market:

STÖHR ARMATUREN, Stoehr Valves

INDUS Vacuum and Cryogenic System, Mumbai is authorized Indian agent/Distributor for sales and marketing of STOEHR Valves, Germany (STÖHR ARMATUREN) for Indian market since 2014.

About STOEHR VALVES

Please check the Catalogue for the STOEHR Valves’ products.

Stoehr Armaturen Catalog

Since the 1960s STOEHR VALVES specialized in the development and manufacturing of valves for gases in liquid and gaseous state. They predominantly work for the industrial gas industry, aerospace, Cryogenic industry, marine technology, energy technology and chemical industry, and in the field of science and research.

Our product range of standardized ambient and cryogenic valves are in sizes from DN4 to DN300. These include high-precision bellows sealed control Globe valves, shut-off valves, manual valves, check valves and gas filters for installation in valve boxes, in vacuum-jackets or in conventional pipes.

Our products are designed for extremes. Cryogenic temperatures of down to 4K or below for processing liquid helium, high pressure levels of up to 1,000 bar, high leak tightness to the atmosphere, compatibility with high media requirements, and short opening and closing times are all examples of the demands handled by STÖHR ARMATUREN products.

STÖHR ARMATUREN is certified according to ISO 9001: 2015 and acts quality-oriented in all areas.

STÖHR ARMATUREN Product Philosophy.

The following features characterize the value and the price-performance ratio of the valves from STÖHR ARMATUREN:

Use of solid material

All pressure-bearing parts are made of solid material – no castings or other manufacturing processes for raw materials are used, to avoid cold leaks at even the lowest cryogenic temperatures.

Bellows sealing achieves high tightness to environment of the first spindle seal

Almost all valve series from STÖHR ARMATUREN are bellow sealed to outside. The highest values for leak-tightness at 1x10E-8 mbar*l/sec to the outside can be achieved, equal to the volume of a drop of water within three years.

Fulfillment of the required industry standards according to European regulations

As a European manufacturer, we comply primarily with European rules. If you require another standard, we will consider your request on a case-by-case basis.

Low maintenance, low spare parts requirement, and low lifecycle costs

Due to our design principles and the high quality of the materials used, maintenance and spare parts requirements for all STÖHR ARMATUREN valves are comparably low. Very low failure rates and long service life results in low lifecycle costs.

Series STICKS 900

stoehr armaturen sticks900

⦁ Easy replacement of the compatible valve inserts

⦁ Prepared for installation into vacuum-jacketed lines

⦁ Cryogenic valve and filter series (globe or control valve, filter) in standard execution

⦁ Cryogenic valve for media temperatures ranging from -271° C to -30° C (2K to 243K)

⦁ Available as straight body (standard) or angle version (optional)

⦁ Low heat input through optimised bodies

⦁ As control valve, high control accuracy for flow control

⦁ Space-saving installation (small footprint) using compact piston or diaphragm actuators, IP-controller mounted on top of the actuator

⦁ Installation position can be horizontal or even upside down (optional: 900TD)

⦁ Nominal pressure: PN 10 / 18 / 25 depending on size

⦁ Nominal sizes: DN15 / DN25 / DN50

⦁ Easy to change the valve function by replacing the insert – for example, for globe valve, change valve insert for a control valve, and vice versa

⦁ Inserts are suitable for all body types

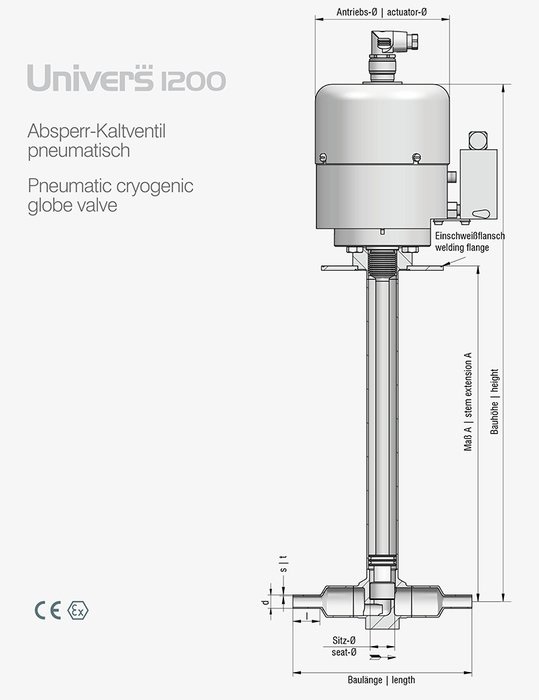

Series UNIVERS 1200 cryogenic and Ambient Valves

stoehr armaturen univers1200

⦁ Available as globe, control or check valve and filter with stem extension

⦁ Cryogenic valve suitable for medium temperatures ranging from -271°C to -30°C (2K to 243K)

⦁ For gaseous media up to 40 bar operating pressure (optional version up to 63 bar available on request)

⦁ Available with manual, pneumatic, electric or solenoid actuation

⦁ Available as straight body (standard) or angle version (optional)

⦁ Adaptable to various environmental conditions (installation in seawater environment, desert or cold conditions)

⦁ For installation in vertical position or inclination of up to a maximum of 30°

⦁ Nominal pressure: PN40

⦁ Nominal sizes: DN10 to DN300

Univers 1200, Cryogenic non-return valve

⦁ reliable and high quality stainless steel non-return valve for cryogenic, gaseous and liquid media. Safely responding with low minimum opening pressure.

Univers 1200, Cryogenic strainer/Filters

⦁ filter unit made from stainless steel with wire mesh or sinter filter for gaseous and liquid media. Standard mesh size of 40 µ; other sizes are available on request.

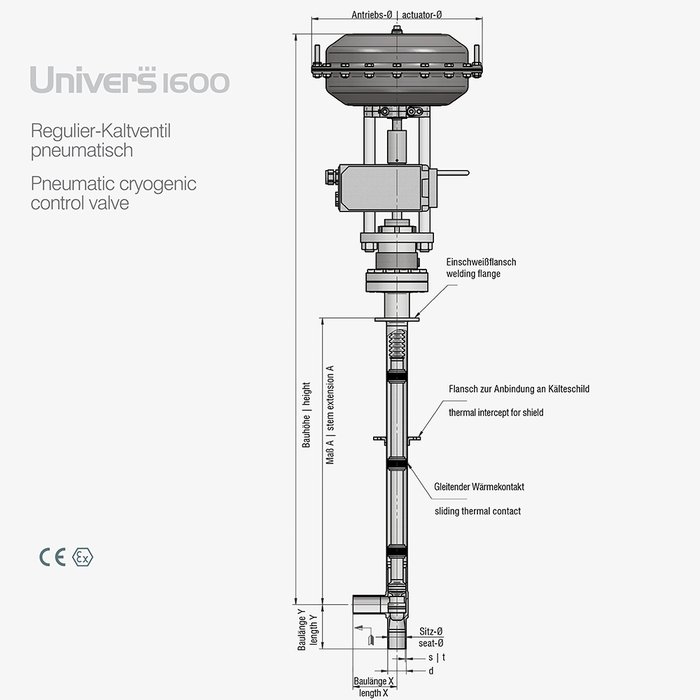

Series Univers 1600

stoehr armaturen univers1600

⦁ Cryogenic globe or control valve

⦁ Medium temperatures ranging from -271° C to -30° C (2 K to 243 K)

⦁ Manual or pneumatic diaphragm actuator

⦁ Angle body type

⦁ High Kv values

⦁ High control accuracy

⦁ Low heat input

⦁ Sniffer bore for monitoring tightness of the bellows

⦁ De-gassing facility

⦁ Numerous options for optimum LHe processing (Cu cold shield on the outer tube of the spindle extension, sliding heat contacts between spindle and inside of the outer tube, non-metallic valve spindles)

⦁ Various control cones for different control characteristics

⦁ Nominal pressure: PN40. Special version available for operating pressures of less than 1 bar

⦁ Nominal sizes: DN2 to DN300

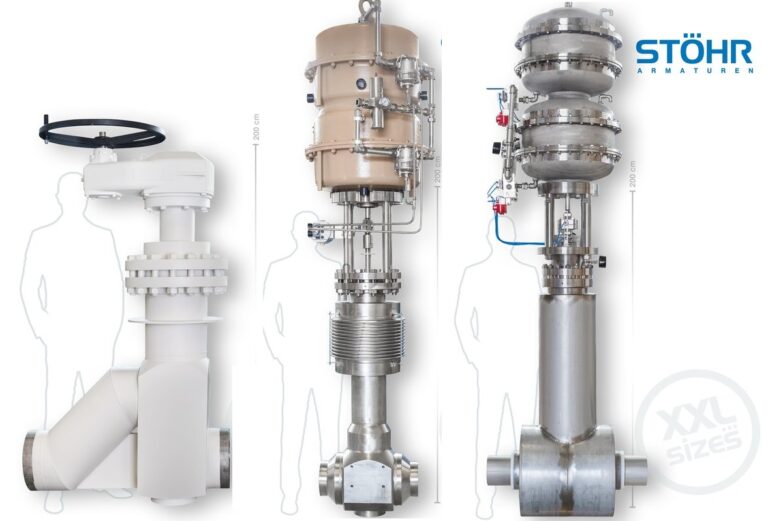

Extreme dimensions: Fittings in "XXL" size

stoehr armaturen xxl sizes

From “XXS” to “XXL” size, our valves meet the highest quality expectations and requirements for acceptance with our customers. Especially for large nominal diameters up to DN300, STÖHR ARMATUREN has developed a family of valves with bellows sealing and strainers adapted from the successful series UNIVERS 1200, UNIVERS 1600 or FREES 1200: control valves, globe valves, check valves and gas filters both for cryogenic or ambient temperatures.

Sealing with bellows protects against leakage to the environment and offers additional safety for man and plant combined with highest energy efficiency possible.

Talk to us. We offer valve solutions for all extremes.

Standard documentation includes the following documents and certificates:

⦁ Acceptance test certificate according to DIN EN 10204/3.1/AD2000-A4 for all pressure-bearing parts

⦁ List of certificates and works certificates

⦁ Quality test certificate according to DIN 55350 Part 18

⦁ Inspection certificate according to EN 10204 3.1

⦁ Declaration of conformity SIL acc. IEC 61508

Detailed operating and maintenance instructions with spare parts proposal is also provided.

STOEHR Authorizations

As a long-standing manufacturer of valves, we have in-depth knowledge of both valve and cryogenic technology, as well as vacuum technology and media compatibility.

All our products based on ISO certification 9001: 2015 and the following certificates:

⦁ DIN EN ISO 9001:2015

⦁ Pressure Equipment Directive (PED) module H

⦁ Welding in accordance with the Pressure Equipment Directive

⦁ AD2000-HP 0 policy

⦁ Approval for the marking according to EN 10204-3.1

⦁ ATEX directive on explosion prevention

⦁ Marine Guidelines of Germanischer Lloyd.

⦁ Guidelines for the supply to the nuclear industry according to KTA 1401

⦁ Individual acceptance tests can be carried out according to your requirements.

Approval certificates: https://www.stoehr-valves.de/en/company/certificates