Valves For Hydrogen System

- HOME

- Cryogenic valves

We’re Hydrogen Ready!!!

We represent STOEHR Valves, Germany in INDIA.

https://www.stoehr-hydrogen.de/

STOEHR Valves is at the heart of optimizing the potential that Hydrogen offers from production, processing, transport, distribution and final application.

We are heavily involved at all stages of the Hydrogen economy and the technological developments to use Hydrogen as Fuel.

STOEHR offers the range of Bellows sealed Valves with pressures up to 900 to 1000 Barg, Filters and Check Valves with best leak tightness and highest reliability for these applications.

The another technique of using Liquid Hydrogen cryogenic storage at 20 K (-252.8 °C), and STOEHR has full range of Cryogenic Bellows sealed Valves (EP, Manual and Control, Filters and Check Valves) for this application to use in Vacuum Jacketed lines and Liquid Hydrogen Storage Tanks.

Another bridging solution under evaluation is Hydrogen combustion engine technology – a robust solution that has the potential to become more rapidly available. STOEHR Valves offers the Complete Valves Package for this.

STÖHR hydrogen valves for future challenges in Hydrogen Applications:

production | transportation | storage | filling | usage

Vehicular Applications

The fuel cells can deliver an efficient on-board power supply, providing electric propulsion. The fuel-cell-powered vehicles will be part of a hydrogen ecosystem. Hydrogen will be stored in high-pressure cylinders and transported to a network of filling stations for use by hydrogen-powered trucks, buses and cars.

Rail Applications

Future fuel-cell-powered passenger trains or cargo trains will contribute to a hydrogen ecosystem – an effective way of decarbonizing heavy rail traffic.

Aerospace and Aviation

STÖHR offers solutions for hydrogen-based transportation systems at all medium temperatures, valve sizes and pressure levels for both space-bound mobile applications and stationary use at rocket engine test benches or launcher filling stations.

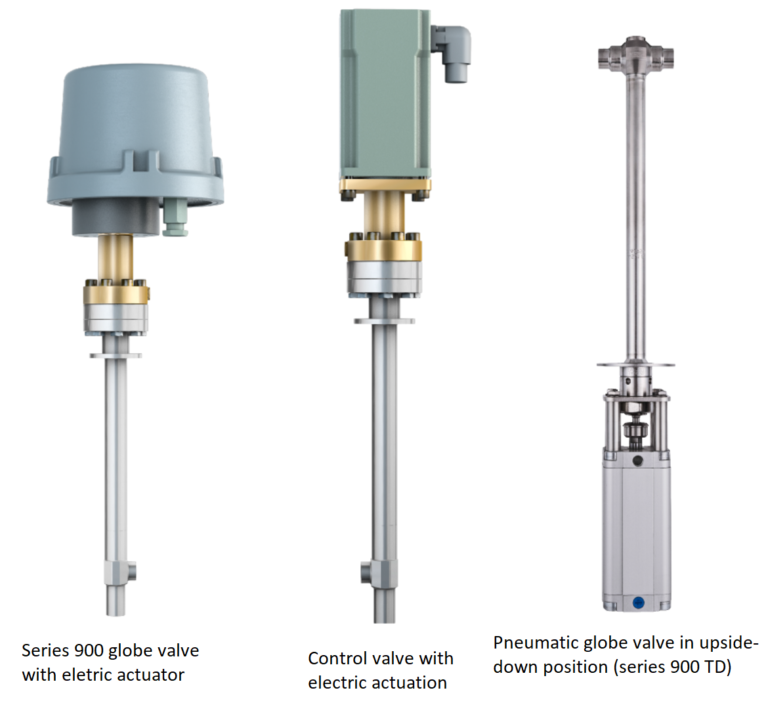

STOEHR Valves for Storage Tank and supply line from LH2 tank to fuel cell, STICKS 900

⦁Easy replacement of the compatible valve inserts Prepared for installation into vacuum-jacketed lines

⦁ Cryogenic valve and filter series consisting of globe or control valve and filter

⦁ Cryogenic valve for media temperatures ranging from 2K to 243K (-271° C to -30° C)

⦁ Available as straight body type (standard) or in angle version (optional)

⦁ Low heat input through optimised bodies

⦁ As control valve, high control accuracy for flow control

⦁ Space-saving installation (small footprint) using compact actuators

⦁ For control valves, IP-controller mounted on top of the actuator

⦁ Installation position can be horizontal or even upside down (optional: series 900 TD)

⦁ Nominal sizes: DN15 / DN25 / DN50

⦁ Nominal pressure: PN 10 / 18 / 25 depending on size

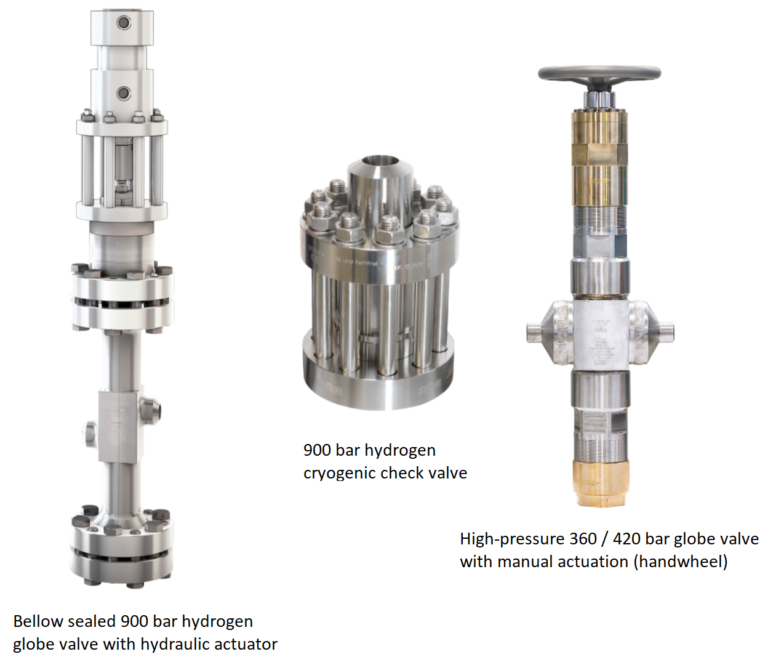

STOEHR Valves for hydrogen storage at high pressure levels, Balans 7100 series

⦁ High pressure valve up to 900 bar nominal pressure

⦁ Ambient medium temperature ranging from -30° C to + 50° C (243 K to 323 K)

⦁ Cryogenic medium temperature ranging from -271° C to -30° C (2 K to 243 K)

⦁ Manual, hydraulic or pneumatic actuation

⦁ Straight body type

⦁ Low actuating forces due to balanced valve lift

⦁ High tightness at seat, even at nominal pressure level

⦁ Installation in any mounting position possible

⦁ Nominal pressure: PN360 / PN420 / PN550 / PN700 / PN900

⦁ Nominal sizes: DN10 to DN40

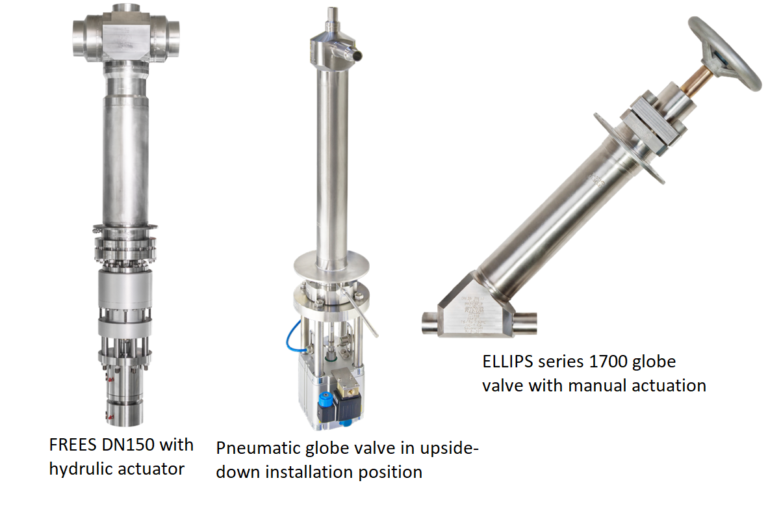

STOEHR Valves for gas storage and distribution centers, Univers 1200/1600 in XXL sizes

⦁ Available as globe, control or check valve and filter with stem extension

⦁ Cryogenic valve suitable for medium temperatures ranging from 2K to 243K (-271° C to -30° C)

⦁ For gaseous media up to 40 bar operating pressure (other pressure levels on request)

⦁ Available with manual, pneumatic, electric, solenoid or hydraulic actuation

⦁ Available as straight body type (standard) or in angle version (optional)

⦁ Adaptable to various environmental conditions

⦁ For installation in vertical position or max inclination of 30°

⦁ Nominal sizes: DN10 to DN300

⦁ Nominal pressure: up to PN40

STOEHR valves mounted on mobile filling crane, Frees 1200

⦁ Free installation position: can be installed in horizontal position or even top-down position

⦁ Cryogenic globe or control valve

⦁ Medium temperatures ranging from 2K to 243K (-271° C to -30° C)

⦁ Straight body type

⦁ Manual, pneumatic, electric or hydraulic actuation

⦁ Nominal sizes: DN10 to DN300

⦁ Nominal pressure: up to PN40

STOEHR Valves for Rocket Test bench

⦁ High pressure valve for operating pressure up to 900 bar

⦁ Cryogenic medium temperature type ranging from 2 K to 243 K (-271° C to -30 °C)

⦁ Ambient medium temperature type ranging from 243 K to 323 K (-30° C to +50° C)

⦁ Manual, hydraulic or pneumatic actuator

⦁ Straight body type

⦁ Low actuating forces due to balanced valve lift

⦁ High tightness at seat, even at high pressure levels

⦁ Installation in any mounting position

⦁ Nominal sizes: DN10 to DN40

⦁ Nominal pressure: PN360 / PN420 / PN550 / PN700 / PN900

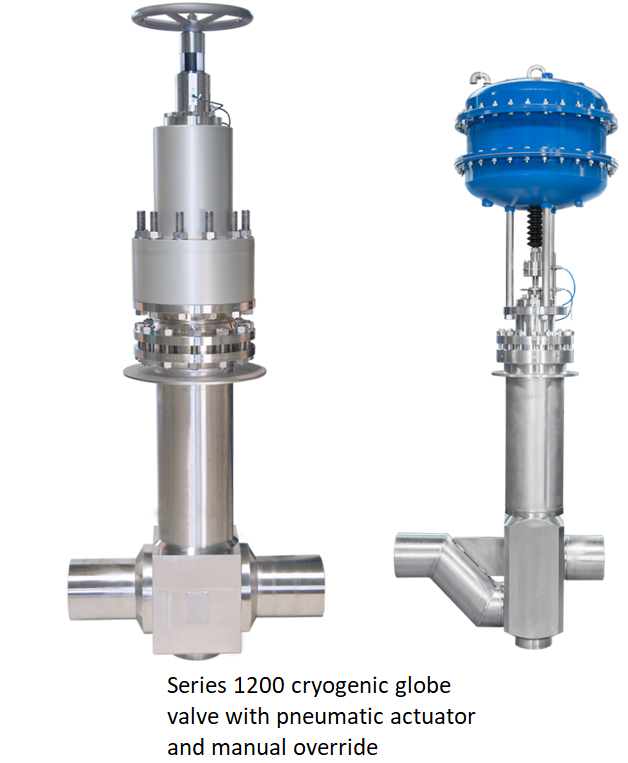

STOEHR Valves for fuel filling for launchers

⦁ Cryogenic globe or control valve

⦁ Crogenic medium temperature ranging from 2 K to 243 K (-271° C to -30° C)

⦁ Ambient medium temperature ranging from 243 K to 323 K (-30° C to +50° C)

⦁ Manual, pneumatic or hydraulic actuator

⦁ Straight or angle body type

⦁ High flow coefficient (KVS/CV value)

⦁ High control accuracy

⦁ Low heat input

⦁ Sniffer bore for monitoring the tightness of the bellow

⦁ De-gassing facility

⦁ Various control cones for different control characteristics available

⦁ Nominal sizes: DN2 to DN300

⦁ Nominal pressure: up to PN40 (standard)

STOEHR Valves for onboard hydrogen powered fuel cell systems

⦁Easy replacement of the compatible valve inserts

⦁ Prepared for installation into vacuum-jacketed lines

⦁ Cryogenic valve and filter series consisting of globe or control valve and filter

⦁ Cryogenic valve for media temperatures ranging from 2K to 243K (-271° C to -30° C)

⦁ Available as straight body typd (standard) in or angle version (optional)

⦁ Low heat input through optimised bodies

⦁ As control valve, high control accuracy for flow control

⦁ Space-saving installation (small footprint) using compact actuators

⦁ For control valve, IP-controller mounted on top of the actuator

⦁ Installation position can be in horizontal position or even upside down (series 900 TD)

⦁ Nominal sizes: DN15 / DN25 / DN50

⦁ Nominal pressure: PN 10 / 18 / 25 depending on nominal size